THERMAL OR STEAM POWER PLANT

Introduction

The thermal or steam power plant is the main source of electric power generation in India. More than 50%of electric power is produced by steam or thermal power plants in India. In this power plant, the heat energy is converted into electrical energy.

The heat energy is generated by the burning of fuel (mostly coal) is used to heat water and generates steam.

This generated steam is used to drive the steam turbine or sometimes steam engines coupled to the generators and thus in generating electrical energy.

The turbine or steam engines that are used in this power plant not only act as prime movers but also as drives for the auxiliary equipment, such as pumps, stokers fans, etc.

Thermal power generation requires coal and an ample quantity of water for cooling purposes.

The thermal efficiency of the steam power plant is defined as the ratio of heat equivalent of mechanical energy transmitted to the turbine shaft and the heat of combustion is quite low i.e about 30% whereas the overall efficiency of the power plant is the ratio of heat equivalent of electrical output to the heat of combustion, i.e about 29%.

In the case of most modern supercritical pressure, thermal power plants using many heat-saving devices’ overall efficiency of the power plant reaches the maximum value of 50%.

There is various type of losses occurring in the steam or thermal power plant. Losses in the boiler house are about 16% and the turbine losses are 55% which constitute 54%losses in the condenser and 1%in the alternator.

Important components of Thermal power plant

1.Coal handling plant -Coal is the most commonly used fuel in thermal power plants. Handling of coal is done between the live storage and the firing equipment.

For controlling the flow of coal according to the load on the power plant gates and valves are included in the system.

2.Boilers– Boilers are used to convert water into wet steam. Boilers form one of the major equipment of the thermal power plant. Boilers used in thermal power plants are of two types

(i) Fire tube boilers -In this type of boiler, the tube containing hot gases of combustion inside is surrounded by water. It is compact in size and has a low initial cost. It is heavier and unwidely and there is a chance of explosion.

(ii) Water-tube boilers- In this type of boiler water is inside the tubes and hot gases outside the tubes.

These tubes are always external to the drum. In comparison to fire tube boilers, it has high evaporation capacity, better efficiency of the plant, high working pressure, safer operation, and takes lesser space.

3. Superheater -Superheater is a device used to converts wet steam into superheated steam.

4. Air Preheater -It is a device in which heat of the flue gases is partially used to heat the incoming air. It increases the overall efficiency of the boiler by raising the temperature of the furnace gases by improving the combustion rate and efficiency.

5.Economiser – In an economizer, heat in flue gases is partially used to heat the incoming feed water.

6.Feedwater pumper –It pumps water in the water tubes of the boiler against boiler steam pressure.

7.Cooling Tower -It cools the condenser circulating water. Condenser cooling water absorbs heat from steam.

8.Condenser – It condenses steam used by the steam turbine. The condensed steam(known as condensate) is used as feedwater.

9. Condenser circulating water pump -It circulates water through the condenser and the cooling tower.

10.Steam turbine –The steam enters the nozzle and is cut by the rotor blades resulting in mechanical energy. According to the action of steam on moving blades, steam turbines are of two types (i)Impulse turbine and (ii)Reaction turbine.

11. Electrostatic precipitator-The exhaust gases leaving the boiler contain particles of solid matter in suspension smoke, fly ash, dust, soot, and smoke. Fuel dust is grater with pulverized fuel. Removal of dust from the exhaust gases is very important which is done by using an electrostatic precipitator.

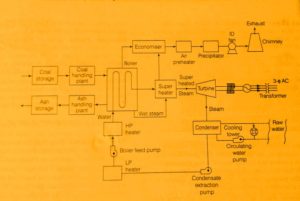

Thermal power plant working

Thermal power plants basically work on the Rankine cycle. The working of the thermal power plant starts with the arrival of coal.

Coal stored in coal storage passes to the furnace through the coal handling plants for the generation of heat energy, and the ash resulting from the combustion of coal collected at the back of the boiler and is removed to the ash storage yard through ash handling equipment.

The heat energy generated by the burning of coal is used to heat the water in the boiler and convert it into wet steam.

This wet steam passes through the superheater, where the wet steam changes to the superheated steam.

When high pressure and temperature, superheated steam passes through the turbine, it gets expanded and moves the prime mover or the turbine. With the turbine, a generator is attached by a shaft that rotates to generates electricity.

The steam after expanding or doing work in a turbine comes to the condenser where it is cooled down to the water by the circulating water. There is a boiler feed pump that is used to feed the water to the boiler through the high-pressure heater.

The high-pressure heater is used to heat the water before passing to the boiler. In this way, electricity is generated in the steam power plant.

Advantages of thermal or steam power plant

1. The fuel used in this power plant is cheaper.

2. It requires lesser space in comparison to hydroelectric power plants.

3. The initial cost is less in comparison to all other types of power plants.

4. This power plant can be at any place irrespective of the existence of the fuel.

5. The production cost of thermal power plants is minimum in comparison to diesel power plants.

6. Such plants can be located near the load centers, while hydroelectric power plants must be installed at the source of water power which is usually isolated from urban areas, therefore transmission costs are reduced.

7. These plants would be able to respond to rapidly changing loads without any difficulty.

8. Steam engines and turbines can work under 25% of overload continuously.

9. A portion of the steam raised can be used as a process steam in various industries like textile mills, sugar mills, paper mills, chemical works, etc.

Disadvantages of Thermal power plant

1. The operation and maintenance cost of this power plant is higher.

2. It pollutes the atmosphere due to fumes and residues from the pulverized fuels.

3.Requires a longer time for erection and put into action.

4. A huge amount of water is required.

5. The handling of coal and disposal of ash is quite difficult in this power plant.

6. Due to the increase in operating temperature and pressure, plant cost increases.

7. The operating cost is higher in comparison to hydroelectric and nuclear power plants.

8. Efficiency falls rapidly below 75%of full loads.