HYDROELECTRIC POWER PLANT

Introduction

The hydroelectric power plant was invented by H.F.Rogers. About 30percent of the world’s total energy requirement is fulfilled by hydroelectric power plants only.

In India, the first hydroelectric power plant was constructed at Mysore in the year 1902 by the name of Shivsamundram having a capacity of 4.5MW.

India has the world’s 5th largest hydroelectric power capacity and the estimated hydroelectric power potential in India is about 1,45,320 MW excluding small hydroelectric power projects. At the end of February 2020, the installed capacity is about 45,700 megawatt. That is only about 10,000 megawatt of hydroelectric power that could be added over the last 10years in India.

Hydroelectric power is the power obtained from the energy of falling water whereas the hydroelectric power plant is the power plant that utilizes the potential energy of water at a high level for the generation of electrical energy.

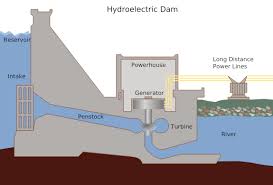

Hydropower plant consists of elements such as a reservoir, dam, forebay, spillway, intake, surge tank, penstock, valve and gates, trash racks, tailrace, draft tube, prime movers, or water turbine.

Construction of hydroelectric power plant

Reservoir

The reservoir in the hydropower plant is used to store water during the rainy season and supply the same during the dry season and hence supply water to the turbines according to the load on the power plant.

Dam

The dam is the most expensive part of the hydroelectric power plant. It is used to create an artificial head and to provide storage of water or the facility of diversion into conduits.

Forebay

Forebay is a type of water tank present just above the intake and it regulates the fluctuation of water. It is used to meet the hourly load fluctuations. Forebay is a must requirement if a power plant is situated away from the storage reservoir.

Spillway

A spillway is made up of concrete and is provided with a water discharge opening shut off by metal gates. Its function is to discharge excess water if the water is more than the capacity of the dam during flood periods.

Intake

It is present at the intake of conduits, tunnels, and flames. It diverts and prevents the entry of wastage and ice into the turbine.

Surge Tank

The surge tank is used in medium and large head power plants. The function of the surge tank is to prevent the penstock/pipe/conduit from the water hammering effect. The surge tank is present at the junction of the pressure tunnel and penstock.

The water Hammering Effect-It is the sudden increase in the pressure on the pipe due to hindrance in fluid motion or direction change. This may cause the penstock to burst if it fails to withstand the pressure.

Penstock

It is a closed conduit or pipe that connects the forebay or the surge tank to the scroll case of the turbine. The penstock is generally made up of steel or reinforced concrete. Also in the penstock potential energy of the water is converted into kinetic energy.

Valves and Gates

Valves are used at or near the entrance to the turbine for the installation employing medium or long-length penstocks or employing a common penstock for more than one unit.

Whereas gates are used in low head power plants at the entrance to the turbine casing to shut off the flow and provide for unwatering the turbine for inspection and repairs.

Trash Racks

Trash racks are made up of long, flat bars set vertically or nearly so and spaced in accordance with the minimum width of water passage through the turbine. These are used to prevent the entry of floating and other materials into the turbine.

TailRace

Tailrace is that part of the power plant where the water after having done its useful work in the turbine is discharged.

Draft Tube

The draft tube is an airtight pipe of suitable diameter attached to the runner outlet and conducting the water down from the wheel and discharging it under the surface of the water in the tailrace.

When the draft tube is used the operating head on the turbine is increased resulting in an increase in output and efficiency.

Prime-movers or Water turbines

The water turbine in a hydropower plant is used as prime movers and its functions are to convert the kinetic energy of water into mechanical energy which is further utilized to drive the alternators generating electrical energy.

Working of hydroelectric power plant

In a hydropower plant, the water in the dam is utilized to move the turbine which in turn runs the electric generator. Then the potential energy of the water stored in the dam gets converted into the kinetic energy of the moving water in the penstock.

And with the help of the combination of turbine and generator the kinetic energy of the moving water in penstock gets converted into electrical energy.

Advantages of hydroelectric power plant

- The running cost of the power plant is the lowest among all power plants (such as thermal power plants, nuclear power plants, etc).

- Fuel transportation cost is nil as no fuel is required, water is the source of energy.

- The efficiency of the power plant is greater than 90%.

- It is highly reliable and the cheapest in operation and maintenance.

- Robust and longer life (life span >50 years).

- It is a very neat and clean power plant as no smoke or ash is produced.

- Less skilled or few skilled persons are required.

- There are no stand-by losses in these power plants.

Disadvantages of hydroelectric power plant

- The construction cost of this power plant is very high

- It takes a long time for an erection.

- As the plants are located in hilly areas which are quite away from the load center so long transmission lines are required.

- It requires a larger area for the establishment.

- The power supply of the power plant gets affected due to the long dry season.

- Hydropower plant firm capacity is low so backup by steam plants is essential.