Types of Capacitor

Nowadays in today’s world of electrical and electronics, there are various types of capacitor are available. And each of these capacitors has its own characteristics and uses. These capacitors are broadly classified into two types, One is on the basis of their work and the second on the basis of the dielectric material used.

Types of capacitor according to work

The capacitor is classified according to work into three types as, Fixed capacitor, Adjustable capacitor and Variable capacitor. Fixed capacitors are further classified as polar capacitors and non-polar capacitors. All three types of capacitor according to their work are discussed here in detail one by one.

Fixed Capacitor

A fixed capacitor is defined as those types of a capacitor whose capacitance value is fixed. It means the value of capacitance of fixed capacitance can’t be changed or altered. Fixed capacitors are normally of greater capacitance value. Manufacturing these types of capacitor is easy due to their less complexity.

Fixed capacitors are further classified as a polar and non-polar capacitor.

Polar capacitor: In polar capacitor positive and negative terminal mark is present on the capacitor. All the polar capacitors are only used in DC circuits only. Polar capacitors are of two types (i) Electrolytic capacitor (ii) Supercapacitor.

Non-polar capacitor: In a non-polar capacitor, there is not any need for a positive and negative terminal. A non-polar capacitor can be used on both ac and dc circuit.

The capacity of Non- polar capacitors are low, but the operating voltage is very high. Non-polar capacitors are of three types such as (i) Ceramic capacitor (ii) Mica capacitor (iii) Film capacitor.

Adjustable Capacitor

Adjustable capacitors are those types of capacitors whose capacitance value can be adjusted with the help of a small screwdriver. These types of capacitors are generally used in transmitter and receivers as for example trimmer, padder, etc.

Variable Capacitor

Variable capacitors are those capacitors in which capacitance value can be varied from its upper limit to its lower limit by rotating the movable shaft present in the capacitor.

Variable capacitors are consists of two sets of Copper or Aluminium plates and the shape of plates is of the form of half-disc. Copper or aluminium plate sets are mounted on a common shaft in which one set is being fixed and the other being movable.

Most of the Variable capacitors are generally gangue capacitors. Variable capacitors are generally used in radio works. Variable capacitors are of two types (i) Trimmer capacitor and (ii) Tuning capacitor

Types of Capacitor according to dielectric material used

According to the dielectric material used in capacitors are classified into various types such as Mica capacitor, Ceramic capacitor, Paper capacitor, Plastic film capacitor, Electrolytic capacitor and Oil dielectric capacitor.

Mica Capacitor

A Mica capacitor is a type of capacitor in which a thin layer of mica sheet is present in between the two metal plates present in the capacitor. The mica sheet used in this capacitor is used as a dielectric medium or insulating material.

Mica capacitors are made in various shapes such as rectangular, round or any irregular shapes. The stack of metal plates and mica sheet which is used in the capacitor is tightly clamped and enclosed in a plastic package.

In case mica capacitor very high value of leakage resistance of the order of 1000MΩ as a result, mica capacitors have a very small value of leakage current and dissipation factor. Mica capacitors are normally in the range of 1pf to 0.1μf with a tolerance of ±1% to 20%.

Mica capacitors can work up to 2500V DC supply and current rating up to about 50A. As a mica capacitor is a type of non-polar capacitor there is no polarity preference present and the value of capacitance and other characteristics can be easily understood by a colour code scheme printed on the mica capacitor package.

Important properties of Mica capacitor

- It is stable and very accurate.

- Mica capacitor has a low tolerance value.

- Resistive and inductive losses are very small.

- Low capacitance value

- It can withstand very high voltage and temperature.

- Characteristics are mostly frequency independent.

Mica capacitors have some disadvantages also such as,

- The cost of a mica capacitor is very high.

- Proper sealing is required in the case of a mica capacitor.

Applications of Mica capacitor

- Mica capacitors are ideal to use for high frequency such as oscillator tuning and RF applications.

- It is used in modern electronic circuits

- It is used in broadcasting instrument circuit.

- It is also used in the high voltage inverter circuit.

Ceramic Capacitor

A ceramic capacitor is a type of capacitor in which ceramic material is used as an insulating or dielectric material. The shape of a Ceramic capacitor is either disc shape or tabular shape.

In disc type ceramic capacitor disc type construction is used. Here a ceramic disc or plate is coated with metals like copper or silver on both sides. In disc type mica capacitor two tinned wire leads are also attached with each plate.

The entire construction unit is packed in a coating of plastic or ceramic to protect it from moisture and other environmental conditions.

In the case of a tabular ceramic capacitor, the inner and outer surface of hollow ceramic tubes is coated with silver which forms the two plates of the capacitor.

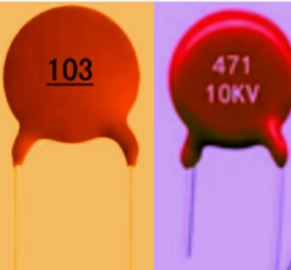

As a ceramic capacitor is a type of non-polar capacitor it does is not possess any polarity. Value of ceramic capacitor is either printed on the capacitor body or a colour code is used for capacitance value.

Ceramic capacitors are normally having a 3-digit number code present on the capacitor body to identify the value of capacitance. In the 3 digit number, the first two digits indicate the capacitor value and the third digit indicates the number of zeros to be added after the capacitor value. Value of Capacitance for ceramic capacitors is generally present in picofarad (pf).

Let us take an example of a ceramic capacitor with a marking of 253. Here 253 indicates 25 and 3 zero’s in picofarad. It means the value of capacitance is equal to 25000pf.

Ceramic capacitors are most suitable for the generation of large power. It can be used up to a current value of 150A and up to a voltage of 5000V at radio frequencies.

Applications of Ceramic capacitor

- It is used to bypass high-frequency noise in power lines.

- It is primarily used as a coupling portion of radio frequency circuits.

- It is also used in resonant circuits.

Paper Capacitor

Paper capacitors are those type of capacitors in which wax paper is used as an insulating or dielectric material. Most of the paper capacitors are cylindrical in shape because these types of capacitors are made by rolling a sandwich of metal and impregnated wax paper sheet into a tube.

Vertical leads are attached to each metal sheet, and the tube is enclosed in wax paper as shown in the figure. The Value of Paper capacitor are normally available is 2.5μf and can work up to a voltage of 2000V Dc supply.

Paper capacitors are the most widely used capacitors due to their low cost and it’s a wide range of capacitance value availability. Paper capacitors are generally designed to withstand very high voltage.

Leakage current in case paper capacitors are very high with a tolerance value of (±10 to ±20) % which is relatively poor, Leakage resistance of this capacitor is of the order of 100MΩ. Due to these limitations, paper capacitors are not used in some of the applications.

This a non-polar type of capacitor so no polarity is present on the body of the capacitor. Value of the capacitance and voltage is generally printed on the body of the capacitor or a colour code is used.

In the case of paper, capacitor wax is used to soak the paper, but the paper deposited with thin metal films is used instead of a separate metal sheet then the volume per unit capacitance can be reduced by 50% and the leakage current is reduced by 90%. Due to this, a structure is created which is more sensitive to be affected by high voltage transients.

Applications of Paper Capacitor

- It is used for both Ac and Dc circuits.

- It is used for high voltage and high current.

- It is used in fans.

Plastic Film Capacitor

Plastic film capacitors are similar to a paper capacitor, In the case of the paper capacitor a wax paper is used as an insulating or dielectric material, But in the case of a plastic film capacitor, a thin sheet of plastic is used as an insulating or dielectric material.

With the use of plastic as a dielectric medium leakage current is minimized, As a result, it provides the properties of the capacitor even at a temperature of up to 150-200○C. Other properties of plastic film capacitors are similar to a paper capacitor.

But in cost, Plastic film capacitors are costlier than paper capacitor due to the higher cost of plastic used. This is the reason this capacitor is only used when a paper capacitor cannot meet the requirement. Plastic film capacitors are generally present in the range of 500pf to 10μf.

Applications of Plastic film Capacitor

- Used in frequency selective circuits.

- Used on oscillators and audio circuits.

- Used for power factor correction and EMI suppression.

- Used in timers and sample and hold circuits.

Electrolytic Capacitor

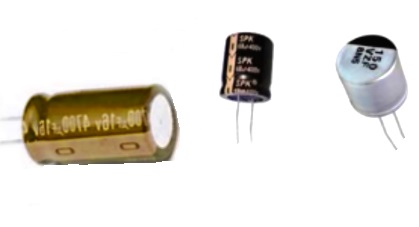

As the name indicates, the electrolytic capacitor uses an electrolyte as one of its plates for achieving the larger value of capacitance per unit volume than other types. In electrolytic capacitors, a layer of aluminium borate, ammonium borate, type of material is electroplated on the positively charged aluminium plate of the capacitor.

Electrolytic capacitors are generally made up of aluminium or tantalum because these two materials form oxides with a very high dielectric strength. These types of capacitors are constructed using two thin films of aluminium foil in which one layer is being covered with an oxide layer as an insulator.

Between the foils, an electrolyte soaked paper sheet is placed. In this capacitor, two foil with electrolyte soaked paper and an oxide layer is present. All these parts of construction are finally placed in a tube.

As an electrolytic capacitor is a type of polar capacitor so positive (+) and negative (-) polarity is marked on the capacitor. In the case of electrolytic capacitor, more emphasis is given to the connection of capacitor in the circuit with proper polarities.

When one connects the positive terminal of the capacitor with the negative terminal of the circuit then due to the chemical action by the electrolyte, the oxide dielectric gets hampered and finally, the capacitor gets destroyed.

It means there is a possibility of explosion if this type of capacitor is wrongly connected with the circuit. These types of capacitors have limited frequency response.

The value of capacitance for electrolytic capacitors is very high in comparison to any other types of capacitance. These capacitors also have a very high voltage range.

Electrolytic capacitors have a tendency to self-heat for types with high ESR. These capacitors have limited frequency response. Leakage current in the case of electrolytic capacitors are also very high which limits its use to some special applications.

Applications of Electrolytic capacitor

- It is used for filtering in dc power supply.

- It also used for decoupling.

Oil Dielectric Capacitor

As the name is given, Oil dielectric capacitor is a type of capacitor which uses mineral oil as an insulating or dielectric material. It is similar to the paper capacitor in various aspects.

The outer body part of the oil dielectric capacitor is made up of aluminium whereas in the case of paper capacitor it is made up of plastic.

The only difference is that of the insulating or dielectric material, in case of the paper capacitor insulating or dielectric material used is paper whereas in case of oil dielectric electric capacitor insulating or dielectric material used is mineral oil (transformer oil).

These types of capacitors are generally used for high voltage and high power applications. Normally these capacitors can work upto25000 V dc supply. The oil dielectric capacitors are generally present at the value of 1μf.

Oil dielectric capacitor is costlier than a paper capacitor. Also, the life span of an oil dielectric capacitor is more than a paper capacitor.

Applications of oil dielectric capacitor

- These types of capacitors are used in certain power supply circuits.

- These are also used in transmitter circuits.